QE Manufacturing

1952

In a small garage in New Berlin, PA., QE Manufacturing started providing precision machined parts and assemblies and have continued with their tradition of excellence for over 70 years.

QE Manufacturing

QE Manufacturing is a progressive, high-precision manufacturer of machined parts and assemblies for the aerospace, military and defense, and commercial industries. Operations include Turning, Milling, Drilling, Grinding, Fabrication, Finishing, Heat Treating, Welding, Engraving, and Assembly. The company also offers quick turnaround for prototypes and small quantity parts for fast delivery.

In 2022 QE Manufacturing celebrated a 70 year “Tradition of Excellence”. Located in New Berlin PA., QE has manufactured award winning AS91000D, ISO9001:2015 Certified and ITAR Registered Contract and Precision machine parts.

QE Manufacturing is committed to providing the Mid-Atlantic area with exceptional value through competitive pricing, superior quality, dependable on-time deliveries, and outstanding customer service.

We work with our customers to develop a mutually beneficial relationship over the long term. We feel that we are an extension of the customer and have a strong commitment and partnership focused on growing long-term relationships that are sustainable, innovative and create joint value.

In a small garage in New Berlin, PA., QE Manufacturing started providing precision machined parts and assemblies and have continued with their tradition of excellence for over 70 years.

QE Manufacturing is a family owned company founded and operated by Robert W. Miller. Robert was later joined by his son, Dale Miller.

QE Manufacturing move to a climate controlled 26,000 sf facility with excellent equipment, personnel and systems.

Matthew and Chrissy Haggerty continue the tradition of excellence as the new owners of QE Manufacturing

QE Manufacturing celebrates their 70th year anniversary

My wife Chrissy and I are extremely excited to have joined the QE family. We are eager to help the company build on its strong tradition of market leadership, service, and innovation. For the past fifteen years, I have been working for and leading my family’s 123 year old media company, Times-Shamrock Communications, headquartered in Scranton, Pa. Prior to that, I practiced law in Scranton for almost 8 years. Chrissy and I live in Scranton and have five children, Abigail, Caroline, Cecelia, Matthew Jr., and Joseph.

The ownership transition brings a renewed focus on QE Manufacturing and their long-term growth. We are committed to investing in the future. We intend to make further strategic investments in areas such as:

I would like to thank Dale Miller and the entire Miller family and everyone associated with QE for having created companies that are well-respected in their community and their industries. I also look forward to continuing the legacy the Miller family has created.

Sincerely,

Matthew Haggerty

President, QE Manufacturing

Matthew was formerly CEO of Times-Shamrock Communications and Managing Director of Elk Lake Capital. He is a graduate of Villanova University and holds an Executive MBA from Villanova University and a Doctor of Law degree from The Catholic University of America’s Columbus School of Law.

QE is an award winning AS91000D, ISO9001:2015 Certified and ITAR Registered Contract and Precision machining job shop serving the aerospace, commercial and defense industries in the Mid-Atlantic area.

QE Manufacturing Proudly Serves:

BAE Systems Small Business of the Year

Lycoming Engines Premier Supplier

Stellant – L3 Communications Bronze Supplier Award

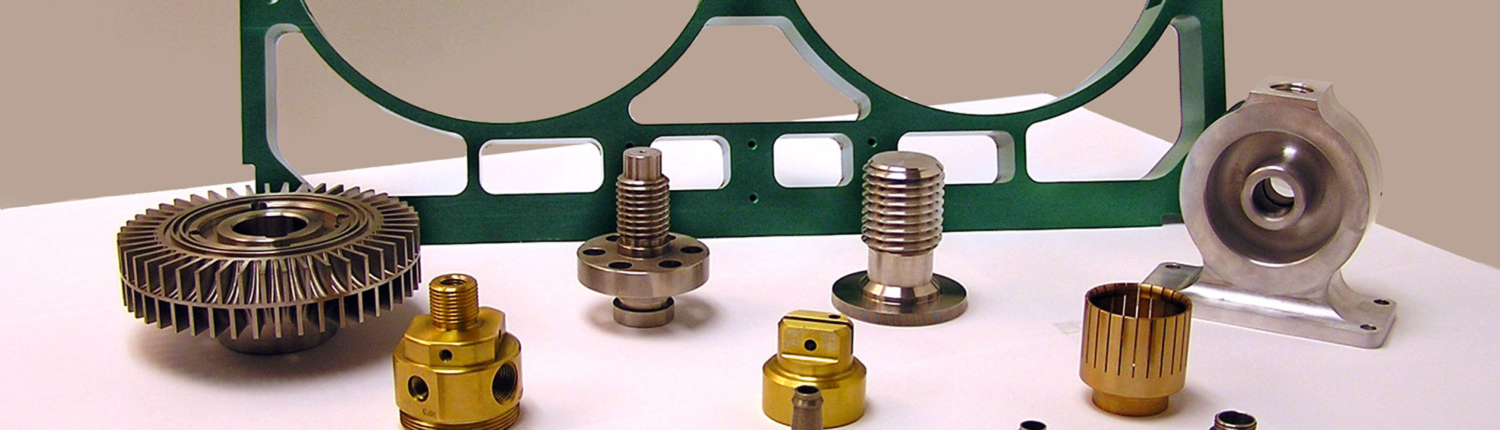

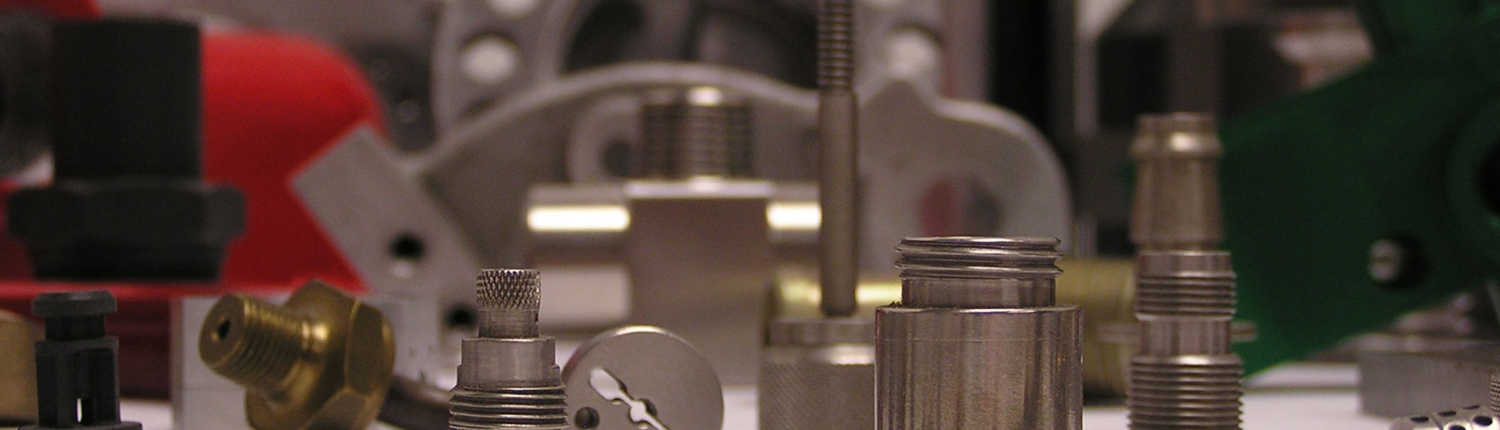

For over 70 years, QE Manufacturing has supplied quality precision machined parts and assemblies to a wide variety of companies and industries. From Fortune 500 companies to small start-ups, our customer base covers industries such as aerospace, defense, electronics, agricultural, medical, machinery, playground and recreational products.

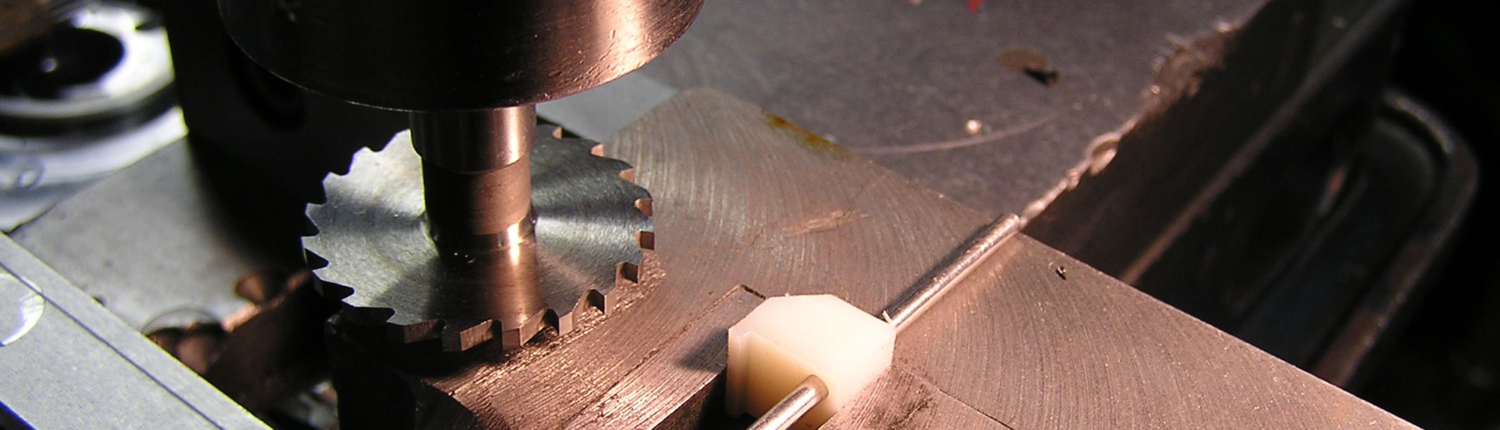

QE Manufacturing uses the latest technology in machining and have experience in working with a variety of materials including aluminum, alloy steel, carbon steel, copper, brass, stainless steel, castings and plastics. Our company is capable of producing various finishes and sizes of parts including prototypes and small to large production runs.

QE Manufacturing is large enough to meet all your machining and assembly needs and small enough to provide personal customer service to each customer. We can manufacture small and large quantities with quick turnaround times.

We continually work hard to separate us from the competition. Our team engages with our customers to develop optimal deliver-ability strategies and practices based on their need.

We provide the right mix of technology, strategy and support to ensure our customers receive their products on-time, all the time.

Turning

1 – Dainichi BX45 Turning Center 2 ½” X 2′ Capacity

2 – TC –20 Takisawa Turning Centers 2″ X 15″ Capacity

1 – TC-2 Takisawa Turning Center 1 ¾” Capacity

1 – TC-350L5 Takisawa Turning Center 2.91″ Capacity

1 – Miyano Turning Center 1 ¼” Capacity

1 – Doosan Turning Center 1 ¾” Capacity

1 – Haas Turning Center 3″ Capacity

1 – #5 Hitachi Seiki Turret Lathe

1 – #4 Hitachi Seiki Turret Lathes

1 – Hardinge Conquest GT27 1 1/16″ Capacity

4 – Omni Turn CNC with 1 1/16″ Capacity

2 – Omni Turn GT-Jr Series 1 1/16″ Capacity

6 – Hardinge Second Operation Machines

1 1/16″ Capacity

1 – 15″ X 4′ capacity Clausing Lathe

1 – 9″ X 2′ capacity South Bend Lathe

1 – 13″ X 3′ capacity South Bend Lathe

Vertical Milling

2 – Haas VF5 CNC Machining Center 50″ x 26″ x 25″

2 – Haas VF4 CNC Machining Center 50″ x 20″ x 25″

1 – Haas Rotary Table with 8 ¼” Chucks

2 – Haas VF2 CNC Machining Centers 30″ x 16″ x 20″

2 – Leadwell CNC Machining Centers (1) 22″ X 16″ X 20″, (1) 40″ X 20″ X 20″

1 – Bridgeport with Line-A-Mill Attachment

2 – Bridgeports with Optical Displays

1 – Bridgeport without Optical Display

1 – Enco

Horizontal Milling

3 – Wilton Tapping Systems

1) ST400B

2) ST800B

1 – ½” South Bend Drill Press

2 – 5/8″ Powermatic Drill Presses

1 – 3′ X 8″ Hercules Radial Drill Press

1 – 6-Spindle Clausing Drill Press

2 – 4-Spindle Allen Drill Presses

2 – 4-Spindle Clausing Drill Presses

1 – 3 Spindle Powermatic Drill Press

4 – Enco Drill Presses

1 – 2-Spindle Rockwell Drill Presses

2 – 10″ Drill Press

1 – 6-Spindle Allen Drill Presses

Grinding

2 – Elite Tool and Cutter Grinders

2 – K.O. Lee Surface Grinders

1 – K.O. Lee Tool and Cutter Grinder

1 – Optima Drill Grinder

1 – 12″ X 24″ Okamoto O.D. Grinder

1 – 12″ X 20″ Shigiya O.D. Grinder

1 – 12″ X 24″ Okamoto Surface Grinder

Fabrication

1 – Rouselle 10 Ton Punch Press

6 – Bench Master 5 Ton Punch Presses

1 – Hydraulic Press 50 Ton

2 – Automator 8 ½ Ton Stamp Punches

1 – Rouselle 25 Ton Punch Press

1 – Royersford 10 Ton Arbor Press

Finishing

1 – Ultramatic Tumbler SV 7, 6.5 Cubic Feet

1 – Gy-Rae Tumbler

1 – Sweco Tumbler

1 – Dynablast-Glass Beaders

1 – Timesaver Belt Metal Finisher

Deburring, Buffing and Polishing Equipment

Painting

1 – 20-25 F Kremlin AirMix Spray System

1 – 20-25 Kremlin Flowmax Spray System (Dry Booth) 6′ x 8′ x 8′

Heat Treating

1 – Lucifer Furnace Model DL82-P24 Chamber

18″ H x 24″ W x 24″ L

Welding

1 – Hobart Mig Welder

1 – Airco, Pulse Arc II 400 Stick Welder

1 – Millermatic Model 350P Mig Welder

Engraving

1 – Gravograph Model IS600 16″ x 24″ Engraving Area

1 – Gravograph Model IS200 3” x 9” Engraving Area

Assembly

Complete Assembiles

Component Parts

Miscellaneous

1 – Sunnen Hones 1/8″ – 5 ½” Capacity

1 – Kaltenbach Automatic Cold-Cutting Saw 5″ Capacity

1 – Abriasive Cut-Off Saw

1 – 16″ Marvel Auto Band Saw

1 – Johnson Band Saw 10″ Capacity

1 – Johnson Band Saw 8″ Capacity

1 – LNS Bar Chamfer Machine

1 – Blackstone Ultrasonic Cleaner Model

SK-6315, 40 Gallon

1 – Demagnetizer

1 – 14 inch Grizzley Band Saw

5 – Heritage Crystal Clean – Part Washer AL80

Gallon Agitatior

Cleaning

Packaging

Multi Axis

1 – Miyano BNX-51MSY 7 Axis CNC Lathe with Y Axis, Sub Spindle, and Superimposition capabilities, with 2.000” Bar Capacity

At QE Manufacturing, we have a Quality Assurance Program that conforms to strict AS9100 Rev. D and ISO9001:2015 Systems.

We have engineering, manufacturing and quality assurance reviews on customers new parts. We take your designs and provide competitive cost manufacturing for on-time deliverability and quality products.

Our operators are trained in statistical process controls, AQP improvements and use the latest equipment along with procedures and work instructions. We have high-tech equipment and the latest inspection equipment to ensure a quality product.

QE Manufacturing stands behind our products and continuously strive to improve our processes and capabilities by investing in equipment, enhanced personnel training, and continuous improvement programs such as six-sigma, lean manufacturing with a zero defect philosophy.

To continually improve while providing on time, products that meet or exceed the needs and expectations of our customers while complying with regulatory statutory requirements.

QE Manufacturing is proud to have the distinction of receiving the AS9100 Rev. D & ISO9001:2015 certifications for quality. Registration AS9100 Rev. D & ISO9001:2015 represents the commitment QE Manufacturing has regarding quality and providing products and services that meet or exceed the customer expectations. AS9100 Rev. D & ISO9001:2015 is a comprehensive quality standard that applies to companies that manufacture products to the end user. These standards have become a worldwide benchmark of excellence in business operations. The standard contains stringent criteria with respect to quality systems and the processing of customer orders. Certification is awarded to those companies which demonstrate a commitment to, and the performance of manufacturing and shipping high-quality products. The achievement marks a milestone in QE Manufacturing’s history as a manufacture of quality machined parts and assemblies.

QE Manufacturing

809 Market Street

P.O. Box 525 New Berlin, PA 17855

Phone: (570) 966-1017

Fax: (570) 966-3505

Email: qesales@qe-man.com

Mid-Atlantic USA

Contact our Sales Manager

Darryl Chappel

Email: darrylc@qe-man.com

"*" indicates required fields